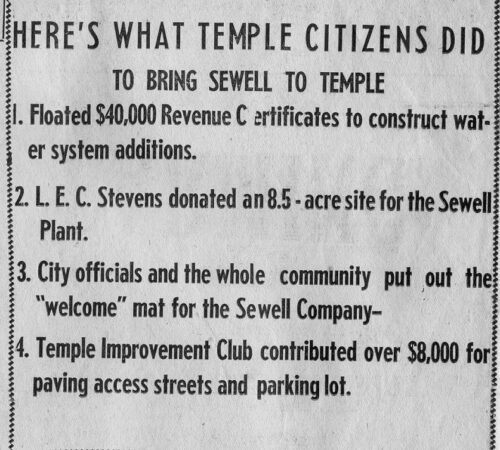

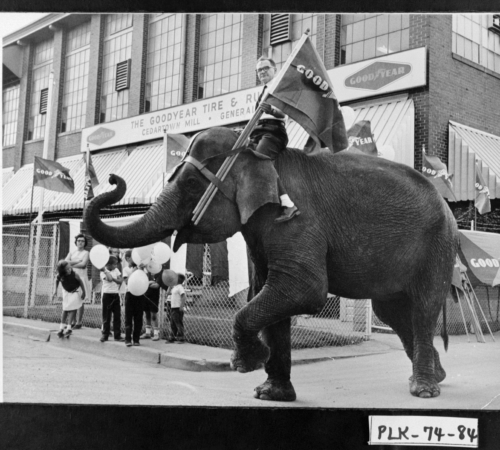

Cedartown, known best for the Goodyear Tire and Rubber Company that produced tire materials and rubber parade floats, was also home to several yarn and cotton mills.

Visit

Things To Do

- Cedartown Depot, 609 South Main Street: The depot houses the town’s Welcome Center and also contains a railroad museum. Constructed in 2004, the Cedartown Depot is a replica of the original Seaboard Airline Railway depot that stood at the same location. The depot is also a Silver Comet trailhead. The Welcome Center is open Monday through Friday from 9:00 am to 5:00 pm, Saturday from 9:00 am to 3:00 pm and Sunday from 1:00 pm until 5:00 pm.

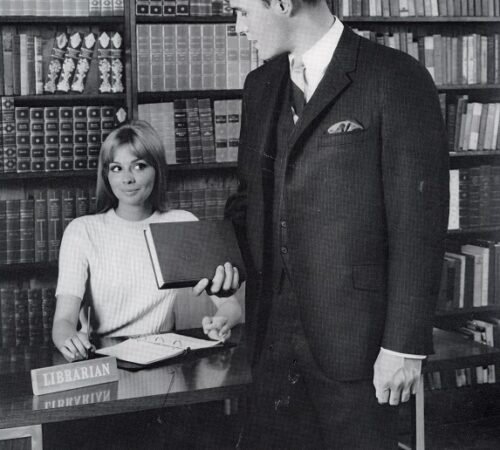

- Polk County Historical Society Research Library, 205 South College Street: The Society is headquartered in a beautiful building on College Street designed by noted Georgia architect Neel Reid. A grant from the state provided extensive renovations and made the building an ideal site for a museum, and in 1980 the building was placed on the National Register of Historic Places, the first structure in Polk County to receive this honor.

- Polk County Historical Society Museum, 117 West Avenue: The museum, formerly headquartered in the original Hawkes Children’s Library, has now moved to the old Southcrest Bank building on West Avenue.

- Silver Comet Trail, 609 South Main Street: The Silver Comet Trail is built on an abandoned rail line, once owned by Seaboard Airline Railroad. This historic rail line has been transformed into a walking/biking trail running through Cobb, Paulding, and Polk counties. Cedartown is right in the middle of of the trail making it a perfect location to see both sides of the trail

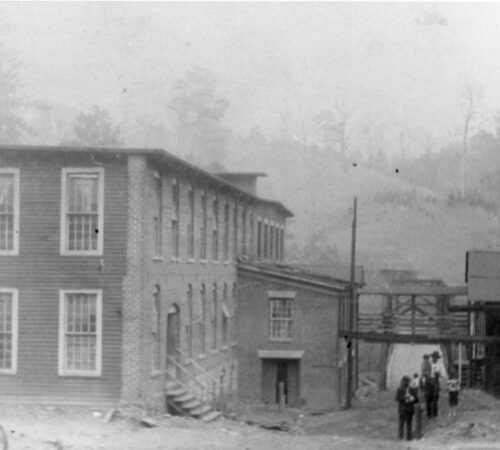

- Cedartown Cotton and Export Co. Mill No. 3 and Mill Village, 591 West Avenue : Mill No. 3 is the last of Cedartown Cotton & Export Co.’s facilities that are still standing. It has since been converted into a flea market. The mill village, located next to the mill, was built during the 1920s. At this time, Charles Adamson began purchasing mail-order “kit homes” for his mill employees to live in. He continued to build homes in Cedartown’s West End.

Places To See

The following properties are not open to the public, but you can view them from the exterior to learn more about the buildings that supported the textile industry here.

- Gildan Inc. Yarn-Spinning Facility, 270 North Park Boulevard: This manufacturing facility produces the yarns used by Gildan Inc. to make t-shirts.

- Blue Springs Finishing and Dyeing Company, 701 Wissahickon Avenue: This location is private property and is not open to the public.

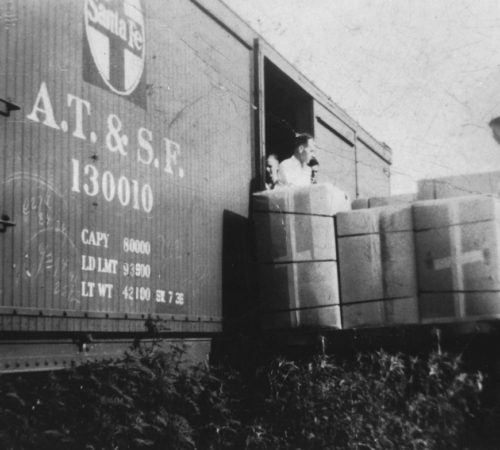

- Cedartown Cotton and Export Company Warehouses, 5991 North 2nd Street: These warehouses were used by the Cedartown Cotton and Export company and stand directly next to where Mill No. 1 used to be.

- Cedar Valley Golf Club, 1811 Buchanan Highway: Built by Charles Adamson, this facility was used to entertain northern textile investors. The Clubhouse is believed to be the original facility.

- Goodyear Clearwater Mill/Paragon Mill and Mill Village, Goodyear Circle: These homes are private property and are not open to the public. Located at on West Avenue and Adamson St. near 2nd and 3rd Streets, the Goodyear mill village covered a radius of 25 city blocks and included a school that Goodyear maintained. Though the Goodyear mill is gone, the mill village, with homes built by both Charles Adamson and Goodyear, is still there.

- Josephine Knitting Mills, 701 Wissahickon Avenue: The Josephine Mill is still standing and is now home to the GEO Chemical Corporation. The brick building with the blue doors, next door to GEO Chemical, is the old Noble Paper Mill and the Kuster Box Plant. Most of the housing constructed for workers at Josephine Mills was located along Cedar and Locust Streets to the west and Prior Street to the south.

- Standard Cotton Mills and Mill Village, 4015 Cedar Hill Street: Although the mill no longer exists, its mill village still stands. These houses were constructed to house the mill workers of Standard Cotton Mills.

- United States Finishing Company, 701 Wissahickon Avenue: : This location is private property and is not open to the public.

- Wayside Inn, 500 West Avenue: The Wayside Inn was built by Charles Adamson in 1920 as a 32-room “mill hotel.” This inn offered rooms for travelers and a fine restaurant. Using a kit ordered from the Aladdin Company of Bay City, Michigan, each piece of the building was individually cut, numbered, and shipped by rail for on-site assembly. The building was demolished in 2021.

History

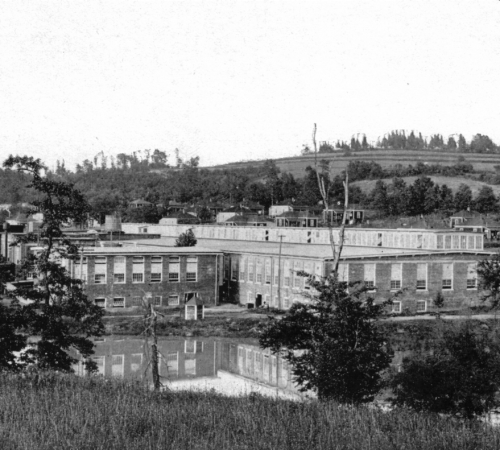

Cedartown was established as part of Polk County in the late 1830s. By the late 1880s, the city saw massive land sales which attracted industrialists like Charles Adamson. Adamson, Cedartown’s first factory owner, purchased land in the city and established a textile mill called the Cedartown Cotton Manufacturing Company in 1894. In 1899, the company expanded by adding Paragon Mills to his company; two years later, he added the Southern Extension Cotton Mill. The Cedartown Cotton and Export Company ran for twenty years producing high-grade hosiery yard. The Cedartown Cotton and Export Company continued to operate its first and third mills into the 1930s.

To house mill employees, Adamson ordered 33 prefabricated mail-order “kit homes” from the Aladdin Company of Bay City, Michigan, and had them assembled on site. The mill village included a playground, children’s nursery, and a mission school. Throughout the 1920s, Adamson continued to build new homes in Cedartown’s West End. Charles Adamson was instrumental in the early prosperity and development of Cedartown but unfortunately, due to the advent of rayon wiping out his fortune; Adamson died a pauper in 1931.

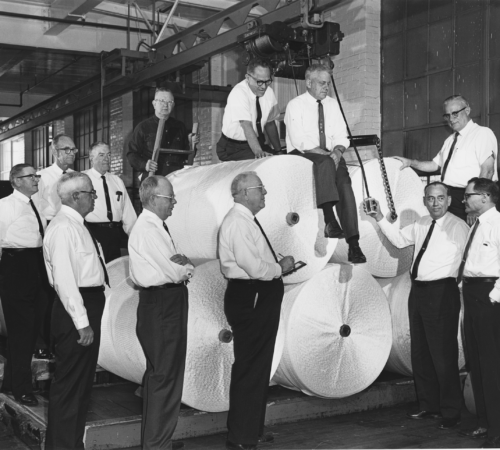

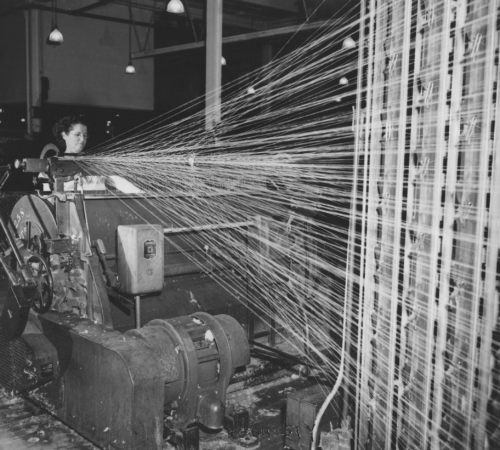

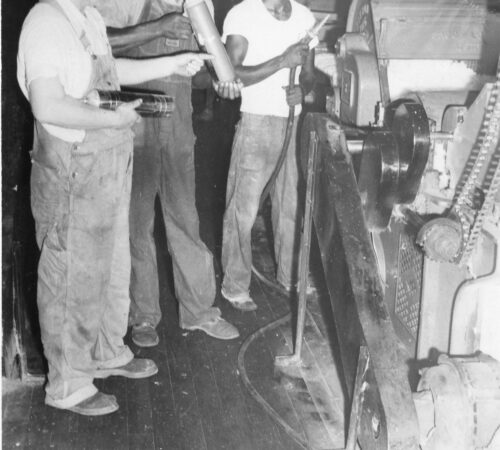

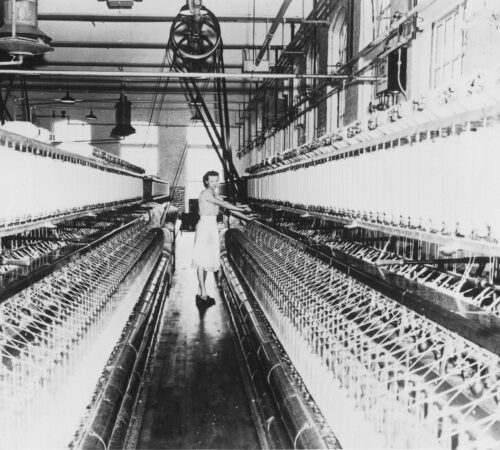

Cedartown was also home to several yarn mills including Standard Cotton Mills, Wahneta Knitting Mills, the Josephine Mills, and more recently Gildan Incorporated’s yarn-spinning facility, which is still in operation today. Standard Cotton Mills opened in 1900 and specialized in the manufacturing of high-grade hosiery, underwear, and yarns. Adding 6,000 more mule spindles to the original mill in 1901, the mill continued to slowly expand during the next few years. In 1902, the Standard Cotton Mill built a second mill to manufacture lower-grade cotton into coarser yarns. The addition of this second mill doubled the capacity of the Standard Cotton Mills.

Standard Cotton Mills ceased operation in 1931 and in 1935, it became the facility of the Uxbridge Worsted Company later known as the Bachman Uxbridge Company. In August 1960 Indian Head Mills Inc. purchased the mills, modernized, and expanded them. Unfortunately, profits slumped in 1963 due to increasingly cheaper foreign imports and the two Cedartown mills closed in 1964. Crown Textile Manufacturing then purchased the mills from Indian Head in May of that same year.

Crown did not put the mills into production and sold them to Hale Manufacturing Company, who purchased the mills to manufacture yarn for the carpet industry in Dalton, Georgia. Hale Manufacturing sold the plant to Polymer Corporation, one of its biggest customers, in 1988. Standard Cotton Mills is no longer standing but the smokestack remains as a reminder of the once-thriving cotton textile industry.

The Josephine Mills went into operation making cotton underwear in 1901 and also built homes for its employees. Cedartown Knitting Company consolidated both Wahneta Knitting Mills and Josephine Mills in 1907, in an attempt to bring back Wahneta Knitting Mills from its closure in 1905. The purchase of the Kuster Box Factory by the owners of Cedartown Knitting added to the mill complex. The Kuster Factory made paper boxes used to package the underwear made at the mills. With 126 of the most modern knitting machines, the capacity and output of the mills were about 500 dozen per day of knit underwear for women and children.

Updates to equipment at both mills in 1903 increased the output of the Wahneta Mill to 200 dozen children’s union suits per day. The Josephine Mills output was increased to 750 dozen women’s underwear. A consolidation of the parent company led to the closing of the Cedartown Knitting Company. Used as a Sunday school, day and night school, and a mission home, the Wahneta Mill building continued the benefit the community into 1907.

In 1916, F. D. Noble, the new owner of the Kuster Box Factory, also purchased the Josephine and Wahneta mills. In the early 1920s, Noble moved his manufacturing operations to Rome, Georgia. In 1923, the United States Dyeing and Finishing Company acquired the Josephine and Wahneta mills and the Blue Spring mill village. The Josephine mill building received an addition while demolition began on the Wahneta mill building. The former Kuster Manufacturing Company paper mill served as the cotton warehouse.

In 1902, the Cherokee Mills opened in Cedartown. Equipped with the best machinery, Cherokee Mills manufactured fine-grade men’s heavy knit underwear. The mill’s president was William Parker who was also general manager of Standard Cotton Mills. Heated by steam and lit by electricity Cherokee Mills was a modern mill for its time. Sold to Standard Mills in 1922, Cook Duck Mill became the new name of the Cherokee Mills. Utilizing twelve acres of land, the Standard Mills complex was an important industrial enterprise in northern Georgia.

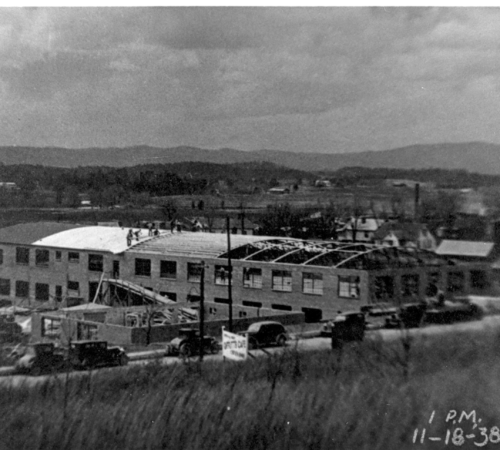

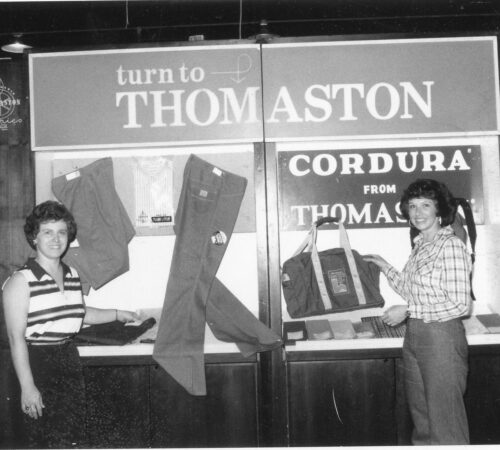

In 1964, Arrow Company, a division of Cluett, Peabody & Co. Inc., opened a mill in Cedartown to make men’s and boy’s shirts. The Cedartown plant was originally designed to produce 4,000-4,200 dozen 100% cotton shirts per week but eventually produced 5,500 dozen shirts per week. The plant was in operation until it closed in 1995 due to slow sales with the rise of the casual dress in the workplace and increased competition from lower-cost overseas textile imports.

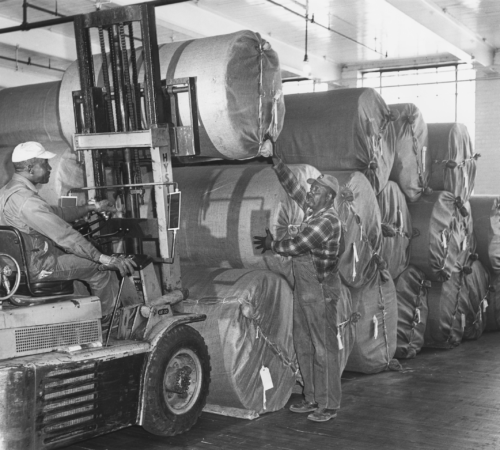

By the early twentieth century, cotton mills began manufacturing tire cord and other textile products for the new automobile industry. These operations proved costly, leading owners to sell the mills to national companies. In 1925, Goodyear Tire and Rubber Company purchased the former the Paragon mills, its first mill in Georgia, to produce cotton cord and cloth for tires.

The Goodyear Clearwater Mill #1 added two additional buildings to the original mill building and 100 additional homes to the mill village. 288 homes were located in the mill village, providing housing for more than fifty percent of the plant employees.

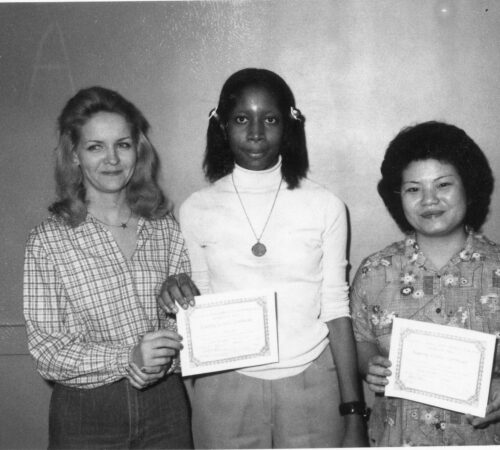

Production at Goodyear Clearwater Mill #1 continued during World War II and African Americans in particular benefited briefly from wartime labor shortages. Working longer hours and sometimes receiving pay increases, some companies hired African American workers to fill production lines, positions not previously available to them. These jobs disappeared after the war and did not return until after Congress passed the Civil Rights Act of 1964. The Goodyear mill closed in 1983, due to several causes including a decline in demand for tire fabric, increased production of smaller tires, and increased use of steel-belted radial tires. Destroyed by fire three years after closing, the mill complex is no longer standing. The mill village remains with both the original mill homes built by Adamson as well as those built later by Goodyear.

With a history steeped in cotton textile manufacturing, Cedartown still boasts a modern manifestation of the industry. In July 1998, Harriet & Henderson Yarns Inc. broke ground on a new yarn spinning facility in Cedartown. In 24-hour operations by October of 1998, the plant supplied the yarn to sock knitters in the Ft. Payne, Alabama area. In 2003, Frontier Spinning Mills and Gildan Inc., in a joint venture, purchased the two yarn-spinning facilities in Cedartown from Harriet & Henderson Yarns Inc., after the company declared bankruptcy. The facilities began operations as Cedartown Manufacturing LLC., spinning cotton yarn for t-Shirts and tank tops. Modernized and refurbished in October of 2012, when Gildan Inc. purchased 100% of the plant, the plant is still in operation in Cedartown.

Charter Trail Members

Resources to Explore

Click on the following links to learn more about this region.

Back to Community List

Email the Trail at wgtht@westga.edu or visit our Contact Us page for more information.