This small town has a textile industry known for its appearance in the famous zombie franchise “The Walking Dead”.

The textile industry was brought into Grantville with the introduction of the railroad, as was the case with many other communities. Grantville Hosiery Mill and Grantville Cotton Mill called this community home and both closed down in 1980. Keep an eye out in AMC’s “The Walking Dead” for the remains of the cotton mill and a ruined cotton warehouse downtown!

Visit

Places to See

The following properties are not open to the public, but you can view them from the exterior to learn more about the buildings that supported the textile industry here.

- Arnold & Baxter Cotton Warehouse, 17 Church Street: The brick remains of this building were used to film AMC’s “The Walking Dead” and still bear Morgan’s message, “Away With You”. It currently serves as a courtyard for the adjoined local restaurant.

- Grantville Freight Depot, 30 Main Street: This train depot was originally built in 1852 to handle both freight and passengers along the Atlanta and West Point Railroad. In the early 1900s, a second depot was built across the street to accommodate passengers only.

- Grantville Hosiery Mill and Mill Village, 78 Moreland Street: This building has been partially demolished. The surviving portion is home to an architectural salvage store. The Grantville Hosiery Mill Village is located along Banks, Shephard, and Rock Streets. These villages consist of mostly one-story, wood-framed houses.

- Grantville Passenger Train Depot, 30 Main Street: This passenger train depot was built along the Atlanta and West Point Railroad.

- Grantville Yarn Mill and Mill Village, 41 Industrial Way: This site was used in the filming of AMC’s “The Walking Dead”. As of 2020, the 100-year-old property is vacant and has been for sale for several years. The mill village for the Grantville Mill is located along Grady, Smith, Maple, and Arnold Streets.

History

Explore this community’s history via the drop-down sections below!

Charter Trail Members

- Grantville Historic Preservation Commission

- Coweta County Convention and Visitors Bureau

- Coweta County Genealogical Society

- Newnan-Coweta Chamber of Commerce

- Newnan-Coweta Historical Society

Resources to Explore

Click on the following links to learn more about this region.

- Facts for Kids

- Digital Library of Georgia

- Georgia Archives Virtual Vault

- Georgia Historical Society

- Coweta County, New Georgia Encyclopedia

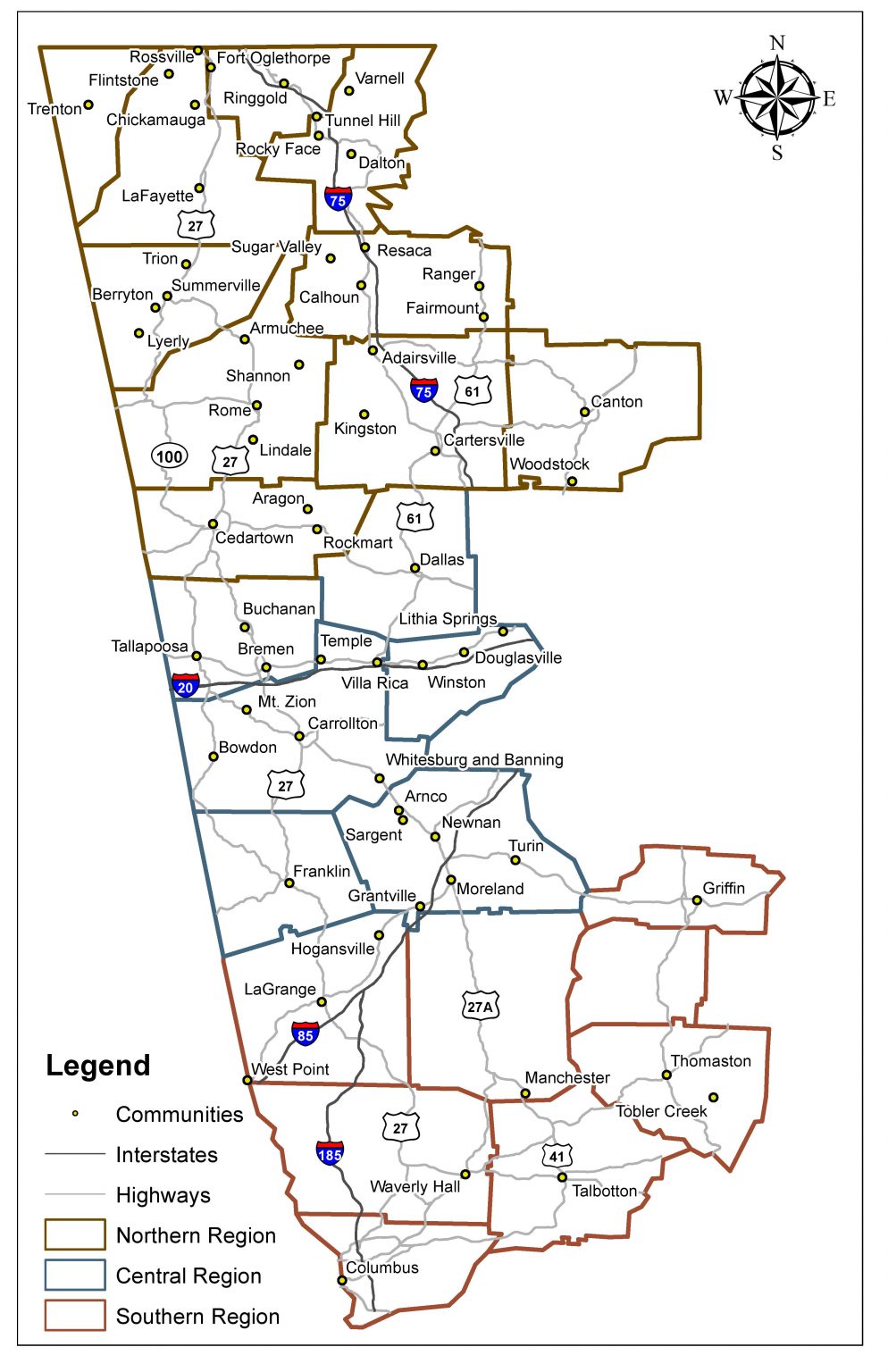

Back to Community List

Email the Trail at wgtht@westga.edu or visit our Contact Us page for more information.