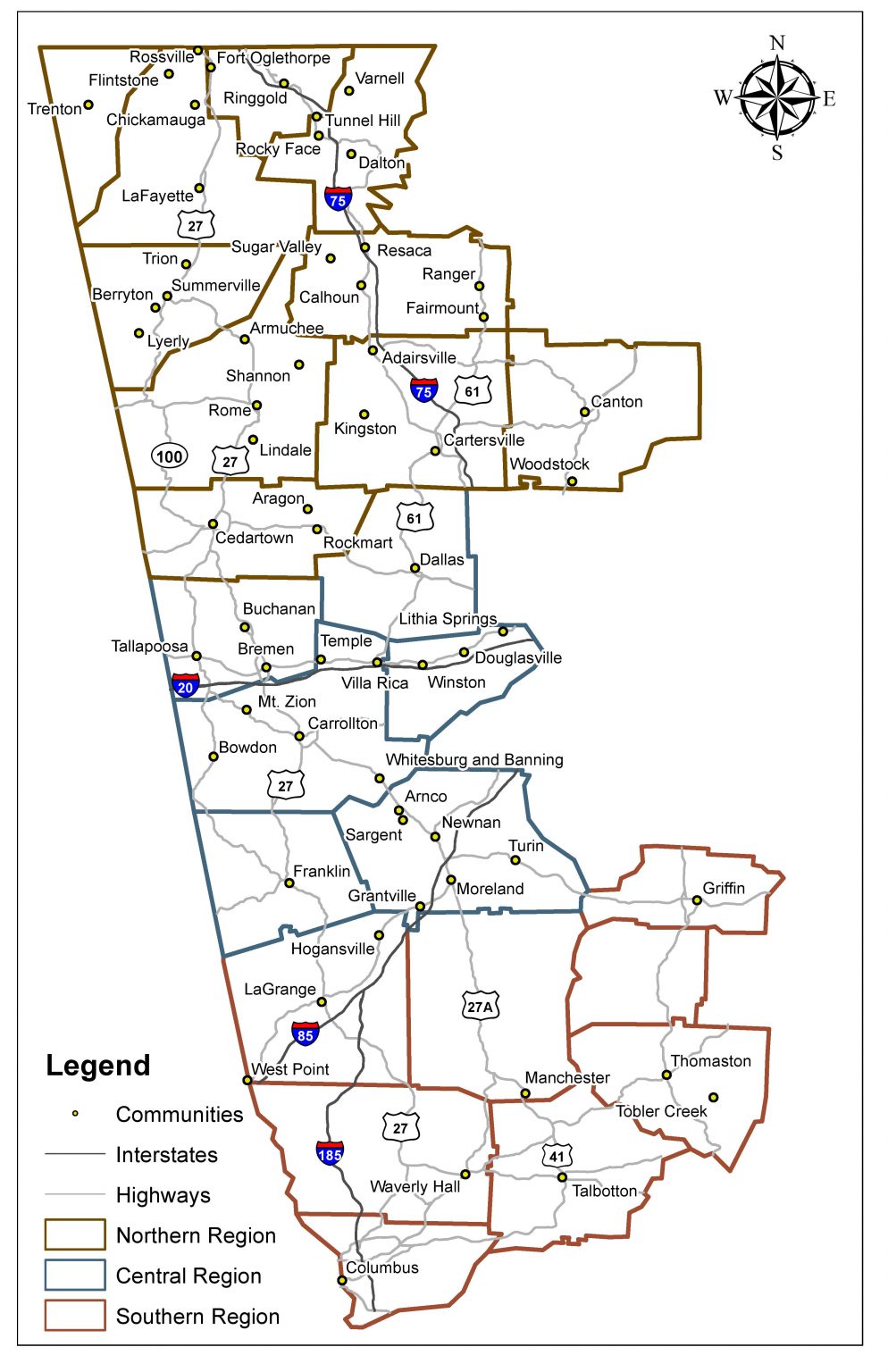

This community hosted two textile mills alongside the hand-tufted bedspread industry lining U.S. Highway 41.

The first textile mill in Cartersville, the American Textile Company, was established in 1904, just 54 years after Cartersville became an established community. American Textile Company operated as the only textile mill in Cartersville until the foundation of Pyramid Mills Incorporated in 1920. Along with these two mills, Highway 41, also known as “Bedspread Boulevard”, was lined with women selling hand-tufted goods to tourists traveling through the area.

Visit

Things to Do

- Bartow History Museum, 4 East Church Street: The Bartow History Museum’s signature exhibit highlights the impact of Goodyear and other textile industries in Cartersville and Bartow County. The museum has an extensive collection of documents and photographs relating to textile industry history. Their hours of operation are Monday through Saturday 10:00 am – 5:00 pm.

Places to See

The following properties are not open to the public, but you can view them from the exterior to learn more about the buildings that supported the textile industry here.

- Shaw Industries Group Incorporated: This location is currently a private business and is not open to the public. Shaw Industries Group Incorporated purchased this tufting mill in 1971. This plant, along with the company’s headquarters in Dalton, became two of the major centers of carpet production in Georgia.

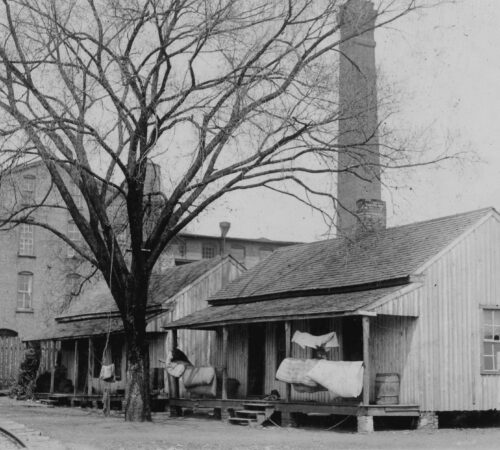

- ATCO & Goodyear Mill and Mill Village, Clearwater Street: Portions of the old mill can still be seen from the street. The old American Thread Company mill building purchased by Goodyear is now mostly gone. This mill village, located near Mayflower Street at Ohio Street, tells the story of those who worked at the mill and lived here. The mill grounds were meticulously maintained and parks were created for family gatherings. In the 1930s, Goodyear expanded the ATCO mill village and continued to support a community for its employees with scout troops, gardening space, a baseball with grandstands, a tennis court, a swimming pool, and more. The Goodyear baseball field is located across from the Goodyear plant where Hometown hero and professional baseball player Rudy York played when he worked at the mill and played for the Goodyear Mill team.

- Bedspread Boulevard: Also known as U.S. Highway 41 and Dixie Highway, running through Cartersville and heading up to Dalton was once a place where women sold their chenille in roadside stands. Travel along this highway to look for remnants of that industry from Cartersville north through Dalton.

- Bartow Textiles, 326 South Erwin Street: Bartow Textiles was built by tufting pioneer B. J. Bandy in 1940. This brick building illustrates the type of factory buildings constructed around the mid-twentieth century to house a growing number of chenille production operations.

- EZ Mills, 1 Johnson Street: This brick hosiery mill was constructed in 1921 and originally featured an expansion interior filled with hosiery machines. Eventually acquired by the Sara Lee Corporation in 1991 the mill closed in 1995. This location is now known as Spring City Technology Park.

History

Established in 1850, in an agricultural region, Cartersville became the seat of Bartow County in 1872. Beginning in the early twentieth century, cotton manufacturing developed in the city and gave way to a thriving carpet manufacturing industry by the mid-twentieth century.

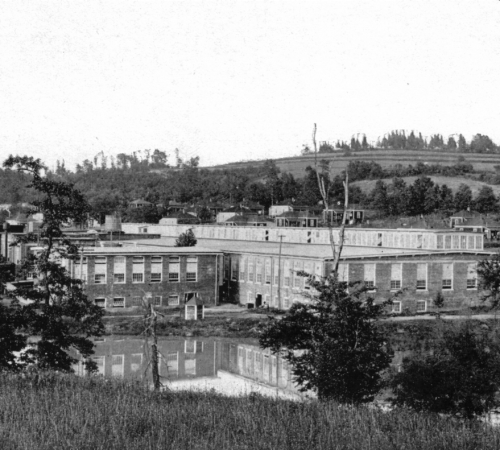

American Textile Company (ATCO) opened the first cotton mill just outside Cartersville in 1904. The company constructed a substantial brick mill building to produce cloth for horse collar pads and an adjacent mill village. After 1917, the Cartersville mill began to manufacture other types of cotton textile products including Duck sheeting, drills, and Osnaburg. Over the next twenty-five years, the horse collar pad business declined as the automobile industry grew and new markets for cloth were found.

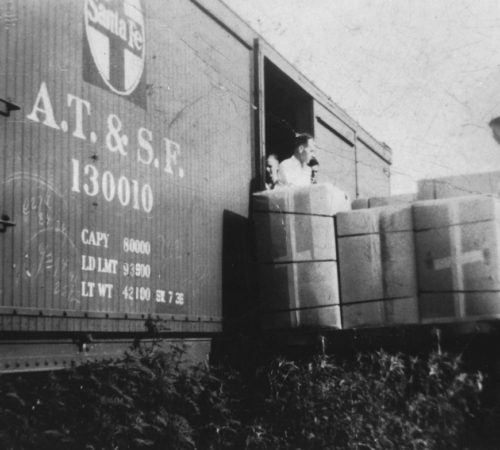

In 1929, Goodyear Tire and Rubber Company purchased ATCO, expanding the mill and the mill village to include almost 300 new houses. The company thrived, producing tire cord for the booming automobile industry. With company-sponsored baseball teams, a scout troop, a recreational park, garden space, and a mill band, the mill village was an enjoyable community for Goodyear mill employees. During World War II, the Goodyear mill and other southern mills focused on cotton and rayon production for tires and produced special fabrics for duffel bags, cartridge belts, tents, and field packs for the U.S. Armed Forces. In the 1950s, the mill expanded to include two new facilities, a rayon mill and a pre-dip unit where fabrics were pretreated for final finishing. With this expansion, the mill was converted to synthetic textile production, which replaced its cotton production. Goodyear closed the Cartersville plant in 2003. The American Thread Company and Goodyear mill buildings were torn down, and the mill homes are now privately owned.

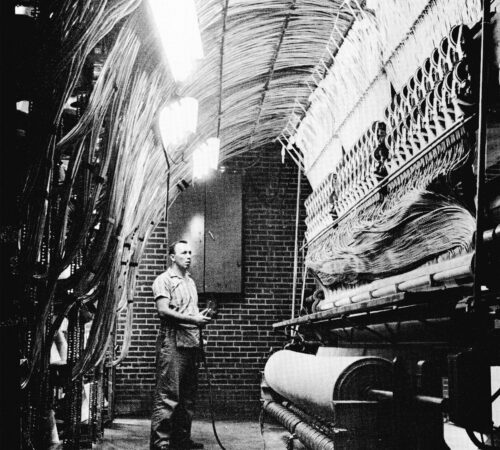

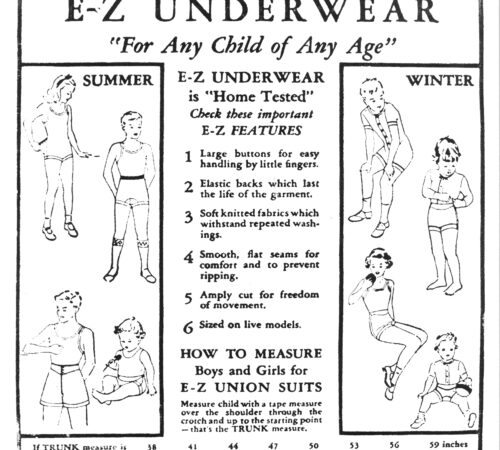

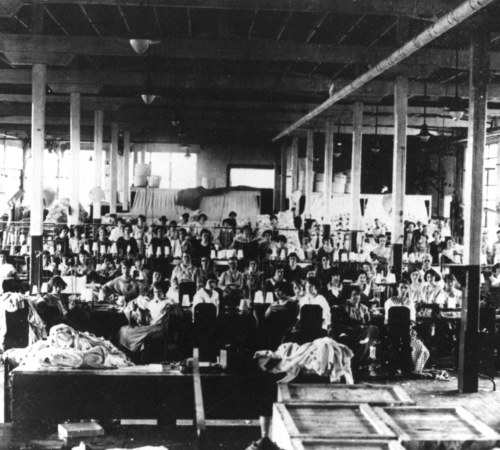

In 1920, a hosiery mill opened in Cartersville to manufacture knit underwear. Known first as Pyramid Mills Incorporated, then as Cartersville Mills, the mill was purchased by the Haight Brothers in 1940 and renamed E-Z Mills. Manufacturing underwear for children and infants, the mills primarily female workforce operated the knitting machines, which made the popular “union suit,” as well as other types of undergarments. In 1969, E-Z Mills converted to manufacturing men’s and boy’s tee shirts and briefs to fulfill a contract with New York-based Cluett, Peabody & Co. In 1976, Cluett, Peabody & Co., Inc. purchased and expanded the mill and increased employment from 618 to 810 employees and changed the mill’s name to Spring City Knitting in 1988. The Sara Lee Corporation acquired the Spring City Knitting Company in 1991. This mill closed in 1992 due to increased international competition following the North American Free Trade Agreement of 1994 (NAFTA).

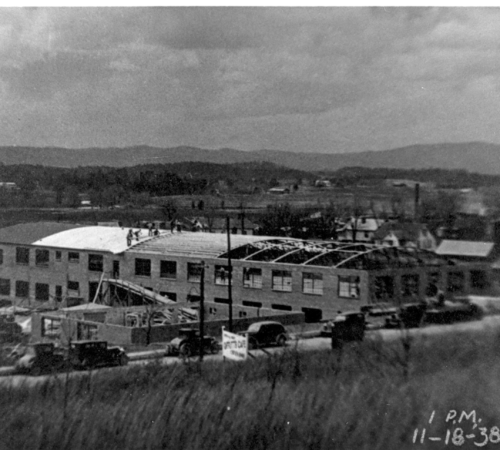

In the early twentieth century, many women in Cartersville and Bartow County were participating in the growing hand-tufted bedspread cottage industry, begun by Catherine Evans Whitener near Dalton around 1900. Women sold their hand-tufted goods along U.S. Highway 41, also known as Old Dixie Highway, Bedspread Boulevard, and later as Peacock Alley, which runs through Cartersville. In the early 1940s, as hand-tufted bedspread production moved from the roadside stands along the Dixie Highway and into factories that produced machine-tufted chenille products, chenille entrepreneurs B.J. Bandy and Dicksie Bradley Bandy opened Bartow Textiles in Cartersville. Bartow Textiles manufactured tufted chenille products such as robes, small rugs, spreads, and draperies.

In 1949, after the death of her father B.J. Bandy, Dicksie Bandy Tillman, and her husband, David Tillman, took over Bartow Textiles. As the chenille business died down in the late 1940s, the company transitioned from yardage machines that were used to produce large swaths of chenille to the broadloom for the production of wall-to-wall carpet. David Tillman at Bartow Textiles was one of the first to experiment with broadloom carpet production. The Tillman’s made the decision to leave the textile business in 1954 because entering into full-scale carpet production would have required heavy investment into refitting old machines and buying new equipment.

Inspired by experimentation with the idea of making broadloom-produced floor carpets, Jack Bandy, B.J. and Dicksie’s youngest son, became an industry leader in carpet production as one of the founding partners of Coronet Carpets. In 1970, Shaw Industries, a company based in Dalton, Georgia, began manufacturing carpet in Cartersville with the acquisition of the Philadelphia Carpet Company. Shaw Industries went on to become one of the world’s largest carpet manufacturers and is still operating in Cartersville today.

Charter Trail Members:

Resources to Explore

Click on the following links to learn more about this region.

Back to Community List

Email the Trail at wgtht@westga.edu or visit our Contact Us page for more information.