This community’s lone textile mill brought about massive expansion and provided numerous jobs.

Founded on the mergence of three railroad lines in 1907, Manchester began its textile industry just one year later. This mill was eventually merged under the Callaway family. The only mill in Manchester closed down in 2002, and the building burned down in 2013.

Visit

Things to Do

- Manchester Train Observation Deck, Broad Street Overpass: The Railfan Observation Deck is ideally located behind the Main Street Shops of Manchester with a perfect view of the RR Yard. Its location allows optimal view of trains coming and going to the Manchester Yard. The gazebo is equipped with two picnic tables and is a great location for photographs! You can expect about 40 trains during a 24-hour period to slowly roll through this Waycross split of Atlanta and Birmingham Mains.

Places to See

The following properties are not open to the public, but you can view them from the exterior to learn more about the buildings that supported the textile industry here.

- Manchester Mill & Veteran Park and Mill Village, 10 Callaway St: This is the location of the ruins of the Manchester Mill. The site has a little park and monument honoring veterans from the Manchester community. You can still see many of the homes developed as the Mill Village surrounding the ruins of the mill. They are privately owned.

History

The city of Manchester in Meriwether County was founded in 1907 when the Atlanta, Birmingham, and Atlantic Railroad decided to extend their rail lines to form a junction of three lines. Fuller E. Callaway, a textile manufacturer from LaGrange, brought cotton production to the small community when he erected the Manchester Cotton Mills, Inc. in 1908. Following the mills establishment, the new city of Manchester was then incorporated on August 16, 1909, to be named after the manufacturing town in England.

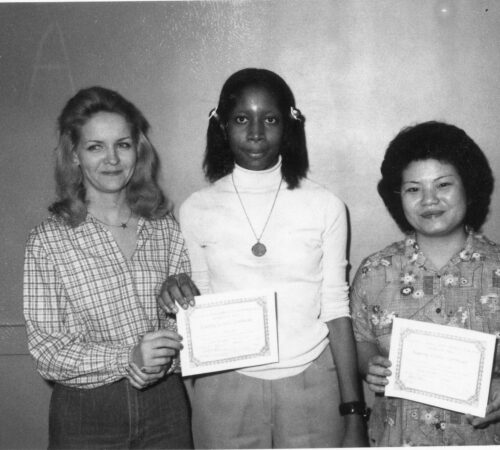

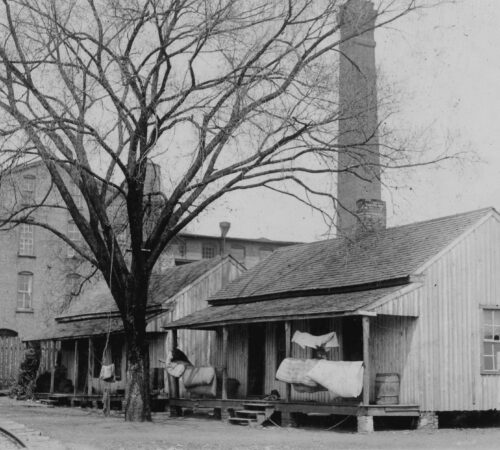

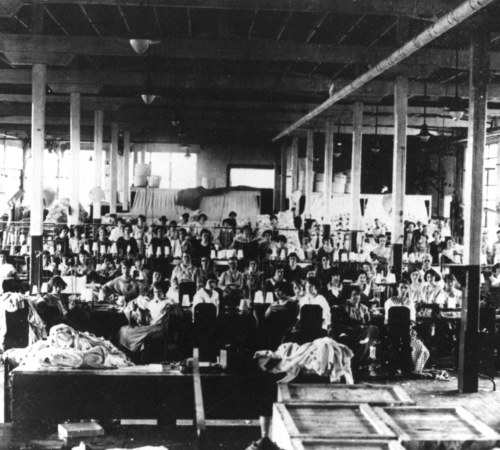

With the railroad and the cotton mill, the town of Manchester quickly grew, drawing in workers from the surrounding countryside. Because of the influx of workers, the town quickly encountered a housing crisis. Callaway helped create the Manchester Development Company to provide mill housing and other city development infrastructure. Businesses, schools, churches, and recreational centers were created, making Manchester one of the largest cities in Meriwether County. Many of the mill houses can still in use today. Overall, the Manchester Cotton Mill Village provided housing, recreation, and a sense of community for the mill workers and their families. Early textile manufacturers encouraged mill village life as a means to entice farmworkers to move off farms and live closer to the factories where they would work.

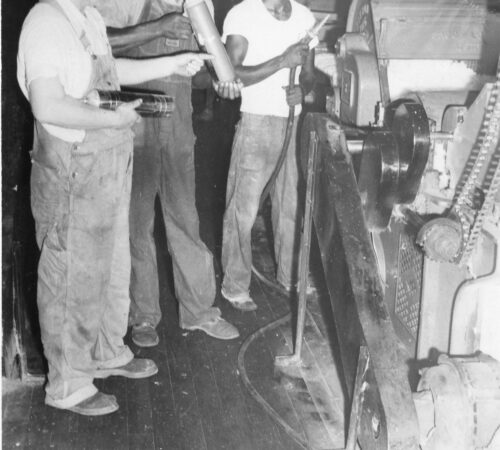

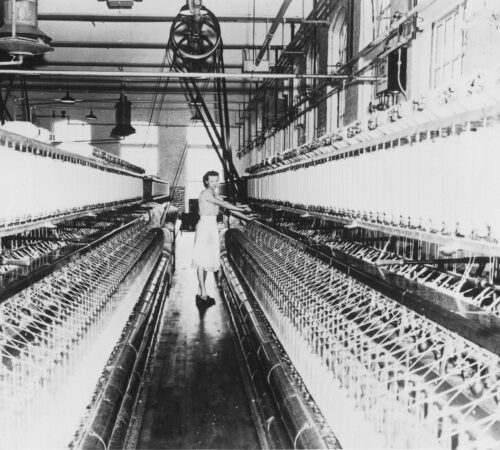

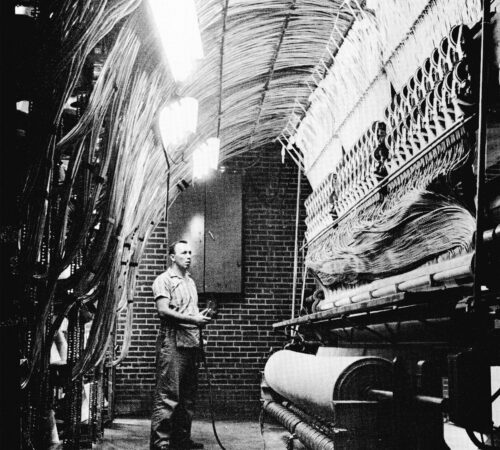

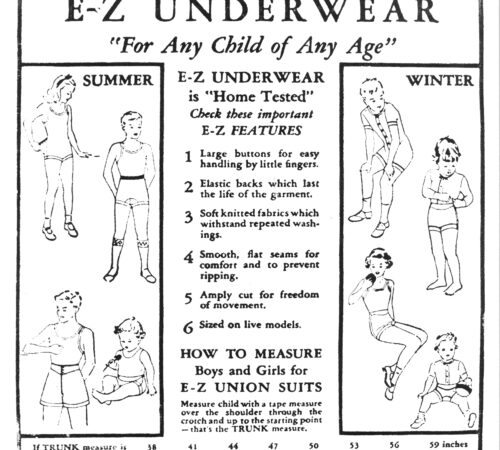

The Manchester mill was located northwest of Main Street across the railroad tracks. The Manchester Cotton Mills, Inc. was owned and operated by the Callaway family with the executive offices located in LaGrange, Georgia. Originally steam-powered, the mill employed around 500 workers to work their impressive 20,800 spindles, 472 looms, and 90 carding machines. The mill specialized in producing cotton duck, sateens, twills, and corduroys until the 1930s. The Callaway family’s careful manufacturing practices and planning in the 1920s allowed their various mills operations, of which the Manchester Cotton Mills was a part, to survive through the Great Depression.

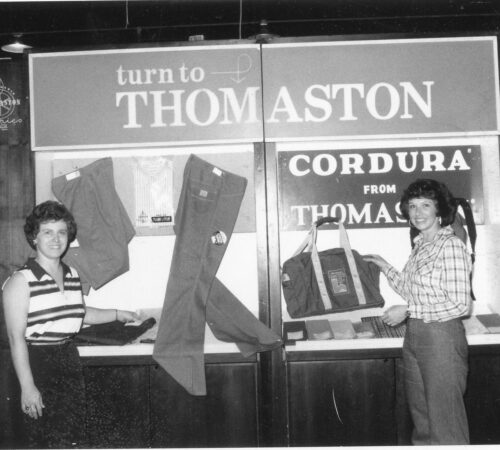

In 1932, the Manchester Cotton Mills Inc. was merged with the rest of the Callaway family holdings to create the Callaway Mills Company. At the same time, the Callaways upgraded many of their factories, and the newly renamed Manchester Plant was converted from steam power to electric by 1935. Products made by Manchester Plant during this time increased to include chafer fabrics, drills, dobby weaves, and novelty fabrics in worsted blends. The mill continued operations through the Great Depression and through both World War I and World War II. Starting in the 1950s, the mill started producing drapery & upholstery fabrics, laundry textiles, drills, sheeting, and twills. At its height, the facility featured 30,480 spindles, 600 looms, and 223 carding machines.

In the 1968, Deering Milliken, a leading textile innovator of new Stabilon laid scrim and Millimatic weft insertion warp knitting technologies based out of South Carolina, bought the plant. Some of Milliken’s products were used in duct tape, roofing membranes, and construction panel manufacturing. Production at Manchester Plant continued until it closed its doors in 2002. The Mill burned down in 2013 in an arson case but visitors can still see the twin smokestacks. Part of the building did survive and has been renovated into an art gallery and studio.

Charter Trail Members

Resources to Explore

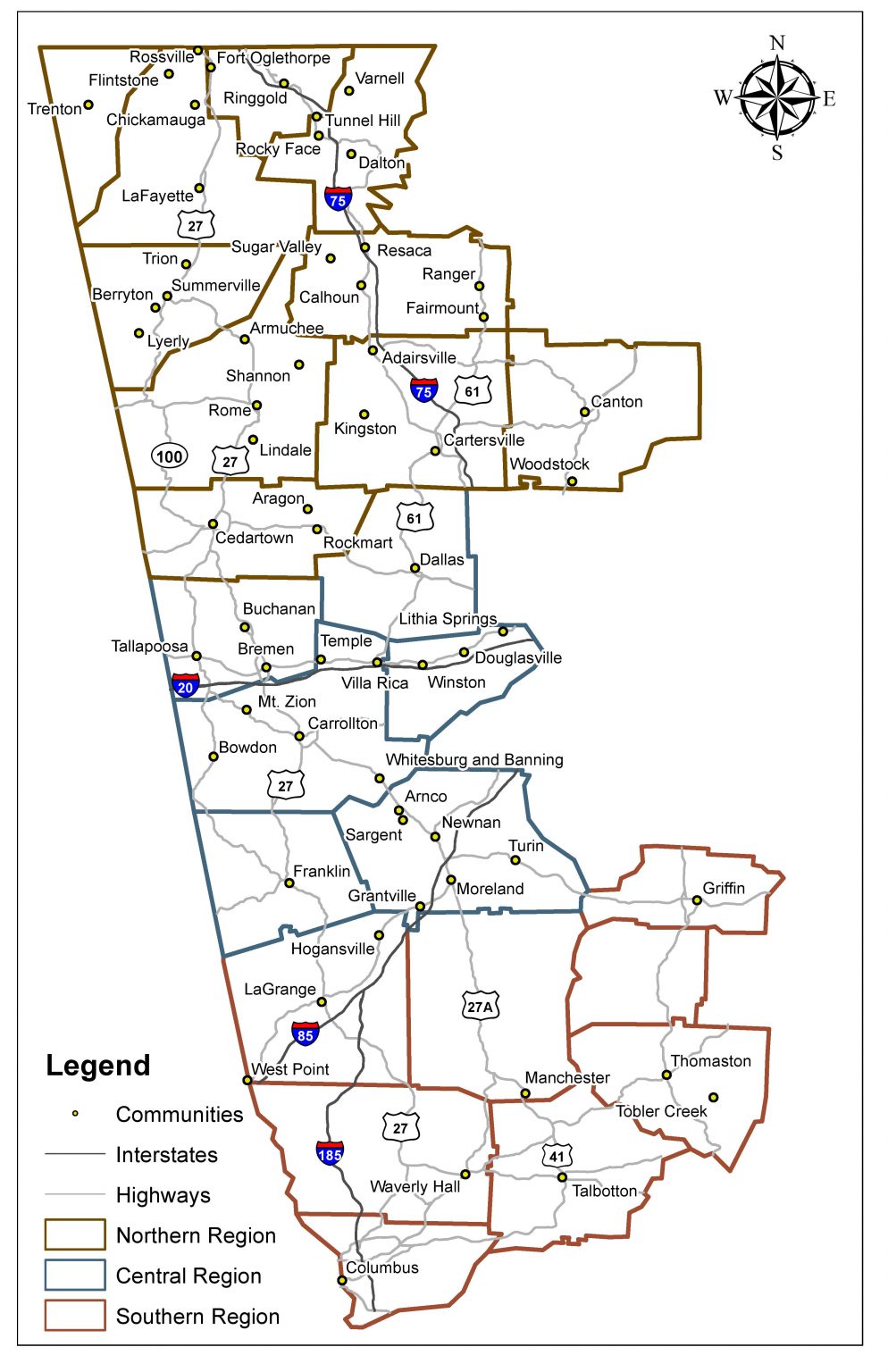

Click on the following links to learn more about this region.

- Meriwether Tourism

- Facts for Kids

- Digital Library of Georgia

- Georgia Archives Virtual Vault

- Georgia Historical Society

- New Georgia Encyclopedia

Back to Community List

Email the Trail at wgtht@westga.edu or visit our Contact Us page for more information.