This single-mill town produced a strong sense of community with its mill village and variety of hosted events.

Shannon’s textile industry hosted only a single mill, but it was a strong foundation for a new community, both figuratively and literally. A large mill village was constructed around the mill, and it hosted a wide variety of events and gatherings for the mill workers.

Visit

Places to See

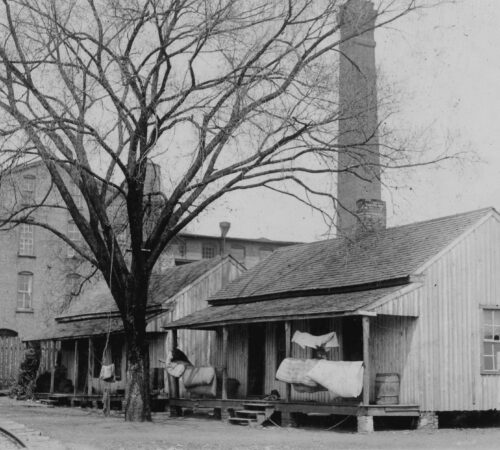

- Brighton Mill and Mill Village, 398 1st Street Northeast: Brighton Mills was constructed in 1925 and opened in 1926 after Shannon was picked as a prime location in the south for a textile mill by William L. Lyall. With this mill came a mill village, which still exists today. Look for houses with hipped roofs, shotgun houses, and houses from the “small house” movement.

History

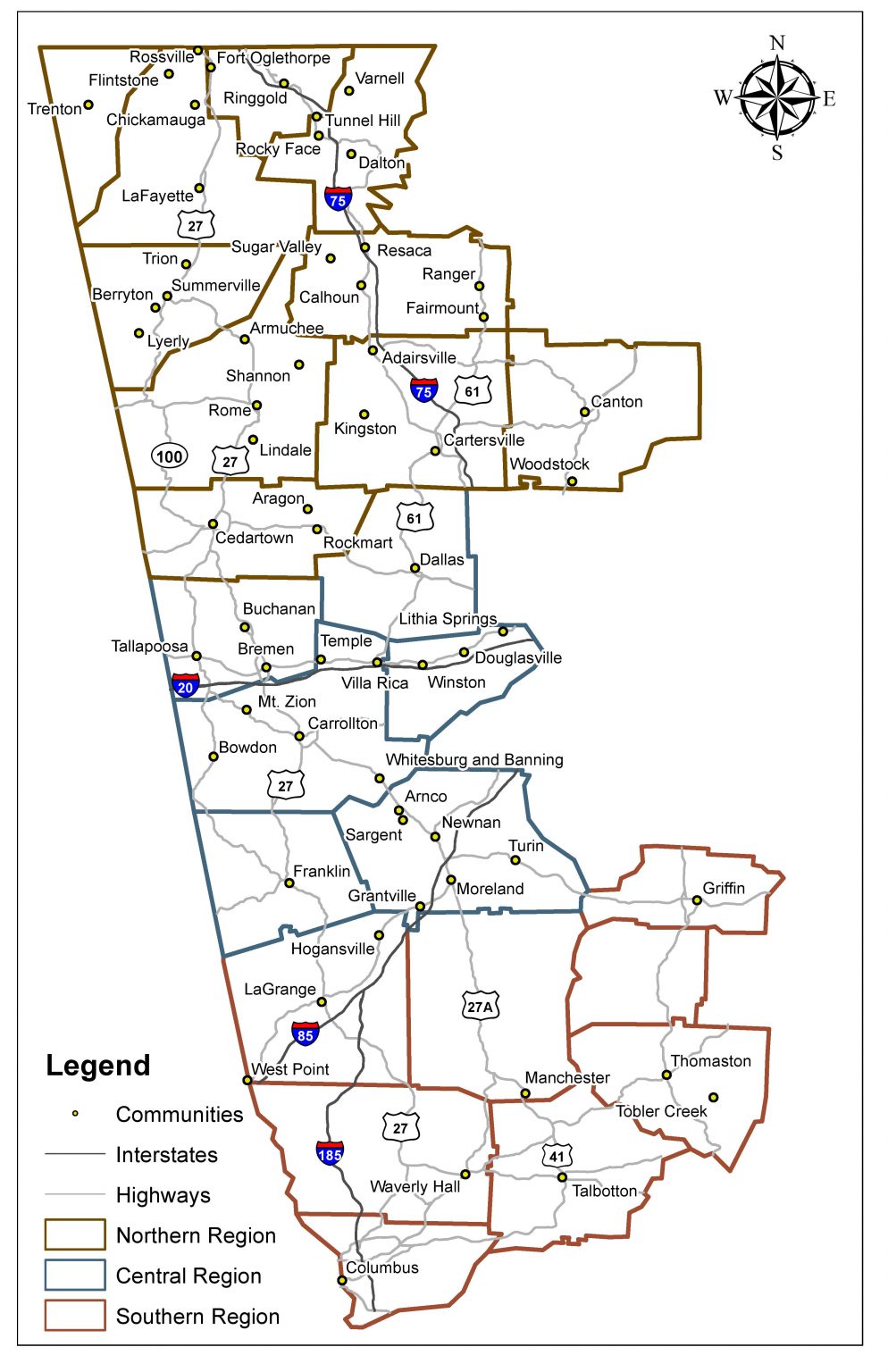

The community of Shannon, just northeast of Rome, Georgia, was once part of Ridge Valley, named after Cherokee councilman Major Ridge. After the forced removal of the Cherokee along the Trail of Tears, Colonel Joseph Watters – a supporter of President Andrew Jackson – built his home in the area. He called the area Hermitage, in honor of Jackson’s Tennessee plantation. In the 1870s, after the Southern Railroad line ran through the community, a northern sawmill operator named E.G. Shannon started a successful cut timber business that shipped large timber from the local railroad depot. By the late 1860s, the railroad stop was informally dubbed Shannon. It was officially renamed on March 31, 1891. Shannon’s location on the railroad was an important factor in its growth in the nineteenth and twentieth centuries.

Textile manufacturing arrived in Shannon in the early 20th century. In 1925, William L. Lyall, president of the New Jersey-based Brighton Mills, chose Shannon out of a survey of many suggested sites in the South to build a new textile manufacturing mill. Two key features that made Shannon an ideal location for the site of the new southern plant of Brighton Mills were its close proximity to railroad transportation facilities, which afforded excellent services for easy movement of goods for Brighton Mills’ already sizeable number of customers, and its water supply, which could support a large manufacturing operation and mill village. Shannon fell along the railroad line that traveled North from Dalton and beyond. Railroad designation 445 serviced the area. Brighton Mills began construction of its new southern mill in 1925. Called the Southern Brighton Mill, the plant opened in April 1926. Part of the contract to build the mill in Shannon included a provision for the construction of 125 cottages for a mill village, which would house mill workers. The community of Shannon rapidly grew with the construction of the mill and the mill village.

By early 1926, Brighton Mills moved a considerable amount of machinery from its Passaic, New Jersey, plant to the new location in Shannon, and began producing tire cord fabrics. By 1927, the Southern Brighton Mills capital investment had increased to $1,200,000 and the mill continued producing automobile tire cord fabrics. That year, the mill used 116 carding machines, 28 broad looms, 25,000 ring spindles, 10,000 twister spindles, 1 sewing machine, 9 pickers, and 1 electric boiler. The plant employed 450 people and sold their products out of their Passaic, New Jersey offices. The following year, Brighton Mills moved the rest of its equipment from its New Jersey plant to Shannon, transferring all manufacturing operations to the renamed Southern Brighton Mills. Southern Brighton Mills established its executive offices in Shannon in 1931 and shortened its name to Brighton Mills with the move.

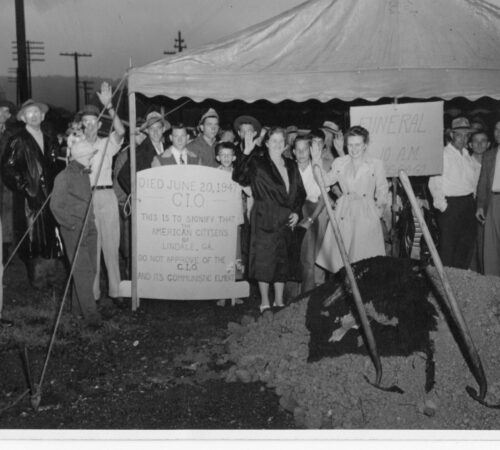

To meet the needs of the growing Shannon community, Brighton Mills created Associated Brighton Employees Incorporated (ABEI) that operated a community baseball stadium and park, swimming pool, pool hall, and even sponsored the Shannon Orchestra. Brighton Mills joined the Northwest Georgia Textile League Baseball Club in 1932. Mill Villages would often have picnics to celebrate the holidays as a community, such as the Fourth of July and Christmas. These events would be day-long celebrations with games, food, and contests. The picnics were not only for the men and women that worked for the mill but for anybody in the community, including children of all ages. The mill would often sponsor field days as a way to bring the community together. Although these families worked in the same mill together, many worked in different departments or on different shifts. Burlington Mills out of Greensboro, NC bought Brighton Mills around 1949 and, by 1951, the Brighton Mill in Shannon changed names to Burlington Mills. Under the new management, the mill made spinning and weaving filament, spun and cotton fabrics, and rayon specialties. Burlington Mills operated from 1951 to 1959, spinning and weaving filament from cotton. After 1960, the mill changed names again to the Brighton Plant of Klopman Mills Inc., a division of Burlington Industries. Around 1994, Galey & Lord purchased and renamed the mill, which operated until it closed in 2004. A large section of the mill building was demolished in 2011, with much of the materials reclaimed and sold throughout the Shannon community. One of the main buildings at the center of the complex has been retained in the hopes that it can be repurposed.

Charter Trail Members

Resources to Explore

Click on the following links to learn more about this region.

- The Watters District Council for Historical Preservation

- Facts for Kids

- Digital Library of Georgia

- Georgia Archives Virtual Vault

- Georgia Historical Society

- Floyd County, New Georgia Encyclopedia

Back to Community List

Email the Trail at wgtht@westga.edu or visit our Contact Us page for more information.