Come visit a textile community that thrived for a century under the operation of just a few individuals.

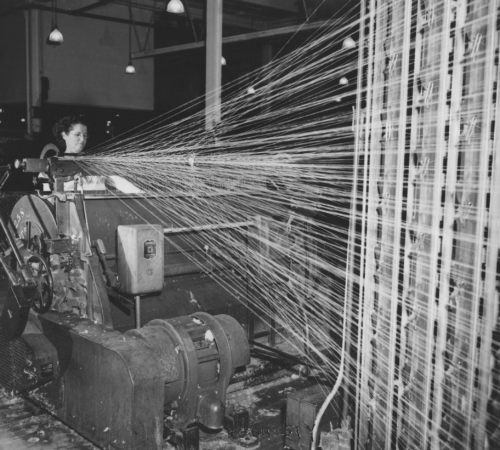

Griffin’s textile industry began in 1883 with the founding of Griffin Manufacturing and expanded rapidly in the following decades. Fighting through race riots, minor strikes, tornados, fires, and economic depression, Griffin’s textile industry steadily built a name for itself. By 1909 Griffin boasted seven cotton mills, including one of the largest towel mills in the world in Kincaid Manufacturing and four mills owned by the Boyd-Mangham group. However, an embezzlement scandal soon brought the Boyd-Mangham mills under new ownership and shocked all of Georgia in the process. Several knitting mills were also added to Griffin’s textile business during the 1910s and 1920s.

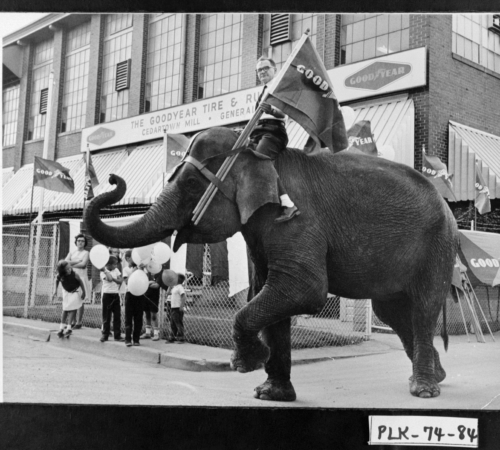

The majority of those cotton mills gradually came under the control of the Cheatham family’s Georgia-Kincaid Mills during the 1920s, while branches of the Shapard family owned the lion’s share of the town’s knitting mills by the 1950s. The Cheatham controlled mills, formerly known as the Georgia-Kincaid Mills, changed names to Dundee Mills after their famous Dundee Towel brand. The story of Griffin textiles revolves around these two families who drove production for the remainder of the 20th century and beyond. Although the Dundee Mills are gone today, companies such as Allstar Knitwear, 1888 Mills, and American Mills keep the textile tradition running strong.

Visit

Things To Do

- Griffin Regional Welcome Center, 143 North Hill Street: The Griffin Welcome Center, constructed in 1899, was originally the Griffin Grocery Company Building. Currently, the building is home to the Griffin-Spalding Chamber of Commerce, the Griffin Downtown Development Authority, the Main Street and Downtown Council office, the Griffin Museum, the City of Griffin Economic Development office, and a banquet room and meeting facility available for rental. The welcome center is open to the public Monday through Friday 8:00 am – 5:00 pm.

- Griffin-Spalding County Library, 800 Memorial Drive: This public library is a branch of the Flint River Regional Library System. Their hours of operation are Monday and Thursday 9:00 am – 9:00 pm and Tuesday, Wednesday, Friday, and Saturday 9:00 am – 6:00 pm.

- Griffin-Spalding Historical Society, 633 Meriwether Street: Founded in 1969 by Seaton Grantland Barnes, John Henry “Jake” Cheatham Jr., and John Hunter Goddard, Jr., the mission of this historical society is to preserve and share the history of Griffin and Spalding County and to promote the preservation and use of their historic places. The Bailey Tebault House, headquarters to this society, has an extensive history that is available to read on the society’s website. The house itself is also available for events such as weddings.

Places To See

- Allstar Knitwear, 841 East Broadway Street: This site is currently active and not open to the public; however, it can still be seen from the road. The owners of this business are relatives of the Shapard family, they have been in operation since 1955.

- American Throwing Company, 335 East Solomon Street: This was yet another Shapard operation, controlled by the descendants of Robert Shapard. It was in operation between the late 1940s and early 1960s.

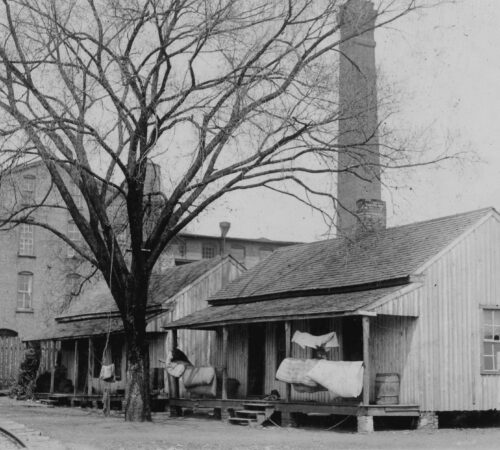

- Cherokee Mills Site and Mill Village, 5 Park Avenue: Cherokee Mills was another mill that belonged to the Boyd-Mangham group of mills. After their collapse, this mill was purchased by Kincaid Manufacturing Company, which in turn became Dundee Mills. This mill became Dundee No. 5, which continued operations through the time that Springs Industries took over. The mill itself has been partially demolished, but portions of it might still be visible at Park Avenue and 6th Street in East Griffin, the address above will take a visitor to the site. The surrounding homes are part of a mill village that was shared with the former Boyd-Mangham Manufacturing Company, which became Dundee No. 3. It was located on the opposite side of the mill village from Cherokee Mills/Dundee No. 5 alongside the railroad track. Both are private properties but can be viewed from the road.

- Crompton-Highlands Mill and Mill Village, 238 Highland Street: While the old Crompton-Highlands mill has been demolished, its mill village still stands. The homes situated on the streets between McIntosh Road and Spring Street, east of Old Atlanta Road and the railroad tracks, are home to the original mill village; look for Highland Baptist Church and the company water tower. The mill site sits between the mill village and the railroad tracks. It is currently a fenced-off field, but portions of the foundation might be visible.

- Dovedown Full Fashioned Hosiery Mills Site: One of the many knitting and hosiery mills built by the Shapard brothers and their family members, the Dovedown Full Fashioned Hosiery Mill building sits at the intersection of West Solomon Street and the railroad. It was originally the site of Griffin Hosiery Mills, but it was renamed in the 1940s. It has been repurposed into offices and currently houses several businesses.

- Griffin Knitting Mills, 830 East Broadway Street: Griffin Knitting Mills was one of the few knitting mills in Griffin which was not controlled by the Shapard family. The building was originally built to house the production facilities of Griffin Buggy Company. By 1925, it had been repurposed as a knitting mill. The company continued operations until the 1960s when it was merged under the name Jaco Knitwear. It later housed Sybil Mills. The building is now split between the Ole Mill Range complex and Wilson’s Grocery. The site is directly across the street from Allstar Knitwear.

- Griffin Manufacturing Co./Thomaston Mills, Griffin Division Site and Mill Village, 670 West Quilly Street: The mill village homes, located off of Experiment Street, are private property and are not open to the public. This is the site of Griffin’s first textile mill, founded by Seaton Grantland and run by W.J. Kincaid for many years. After its collapse in the 1920s it was bought by the Hightower family of Thomaston and consolidated into their Thomaston Mills. It continued operations under Thomaston Mills until the company declared bankruptcy in the early 2000s. It is now used as a warehouse. Many of the homes surrounding the site are remnants of the mill village built to house workers at Griffin Manufacturing Co.

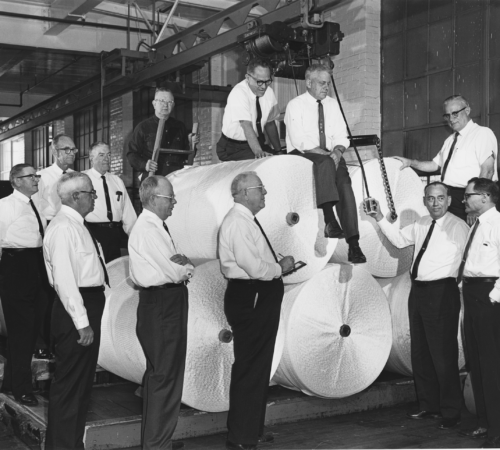

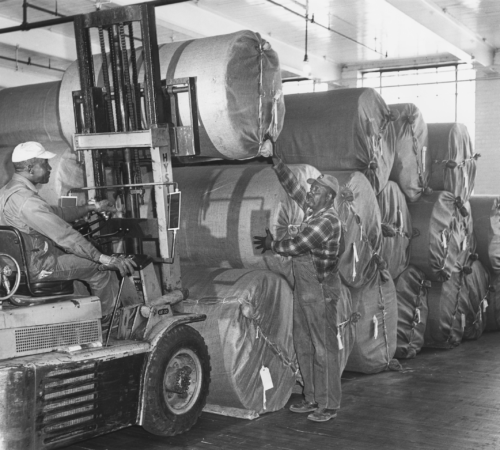

- Kincaid Manufacturing Co., Lowell Bleachery South, and Mill Village: A visitor driving northwest along Experiment Street can see to their right the demolished foundations first of Kincaid Manufacturing/Dundee No. 1 and then Lowell Bleachery South. Kincaid Manufacturing was the second mill to ever be built in Griffin and was named for its founder, W.J. Kincaid. It was one of the largest mills in town when it merged with Georgia Cotton Mills in 1924 and formed Georgia-Kincaid Mills. The new company was later renamed Dundee Mills after their most famous brand. Lowell Bleachery South was built by Kincaid Manufacturing in partnership with Lowell Bleachery of Massachusetts. Kincaid Manufacturing bought out Lowell’s interest and the bleachery became a division of Georgia-Kincaid shortly thereafter. The shared mill village of these two plants can be seen at Bleachery Street, Cheatham Street, Poplar Street, Peachtree Street, and Elm Street.

- Planter’s Cotton Warehouse, 310 East Solomon Street: This site was originally used as a cotton warehouse. It is now home to several local businesses.

- Rushton Cotton Mill Site and Mill Village, 1240 Lyndon Avenue: Rushton Cotton Mills was built by Benjamin Rush Blakely in 1899. It was hit by a tornado and largely destroyed in 1908, but was quickly rebuilt. Rushton Cotton Mills was run by Blakely and his associates until John Cheatham bought a controlling interest in 1927. From that point, it was run by the Cheatham family until it was absorbed into Dundee Mills as the Rushton Division between 1978 and 1980. It was purchased by Springs Industries along with the rest of Dundee Mills in 1995; it was shut down along with the rest of the former Dundee Mills in the mid-2000s. Today the site is home to local businesses. Although it is still private property, it can be viewed from Moody Street and Lyndon Avenue. Many of the homes in the immediate vicinity were constructed to house Rushton’s workers.

- Spalding Cotton Mills/Dundee Mill No. 2 Site and Mill Village, 802 High Falls Road: Some remains of this 100-year-old site can be viewed near the intersection of High Falls Road and 2nd Street in East Griffin. Spalding Cotton Mills was originally built as part of the Boyd-Mangham group of mills. After their collapse, it became part of Georgia Cotton Mills, which in turn became Dundee Mills. The former Spalding Cotton Mills became Dundee No. 2 and absorbed the former The Central Mills/Dundee No. 4 in 1937. The homes in the mill village, many of which are hipped-roof or side-gabled duplexes typical of most southern mill towns, can be viewed along Spalding St or High Falls Road, Solomon Street, Lakeview Avenue, 2nd Street, Chandler Street, and Little Street.

- Spalding Knitting Mills, 324 East Broad Street: This building was originally built to house Norman Buggy Company. By 1949, it had been bought by Spalding Knitting Mills, Robert Shapard’s first operation, which had originally been located downtown. It currently houses several local businesses.

History

Explore this community’s history via the drop-down sections below!

Charter Trail Members

- Three Rivers Regional Commission

- Griffin-Spalding County Library

- Griffin-Spalding Chamber of Commerce

- Griffin-Spalding Development Authority

- Griffin-Spalding Historical Society

Resources to Explore

Click on the following links to learn more about this region.

- Spalding County Newspaper Archives

- Facts for Kids

- Digital Library of Georgia

- Georgia Archives Virtual Vault

- Georgia Historical Society

- Spalding County, New Georgia Encyclopedia

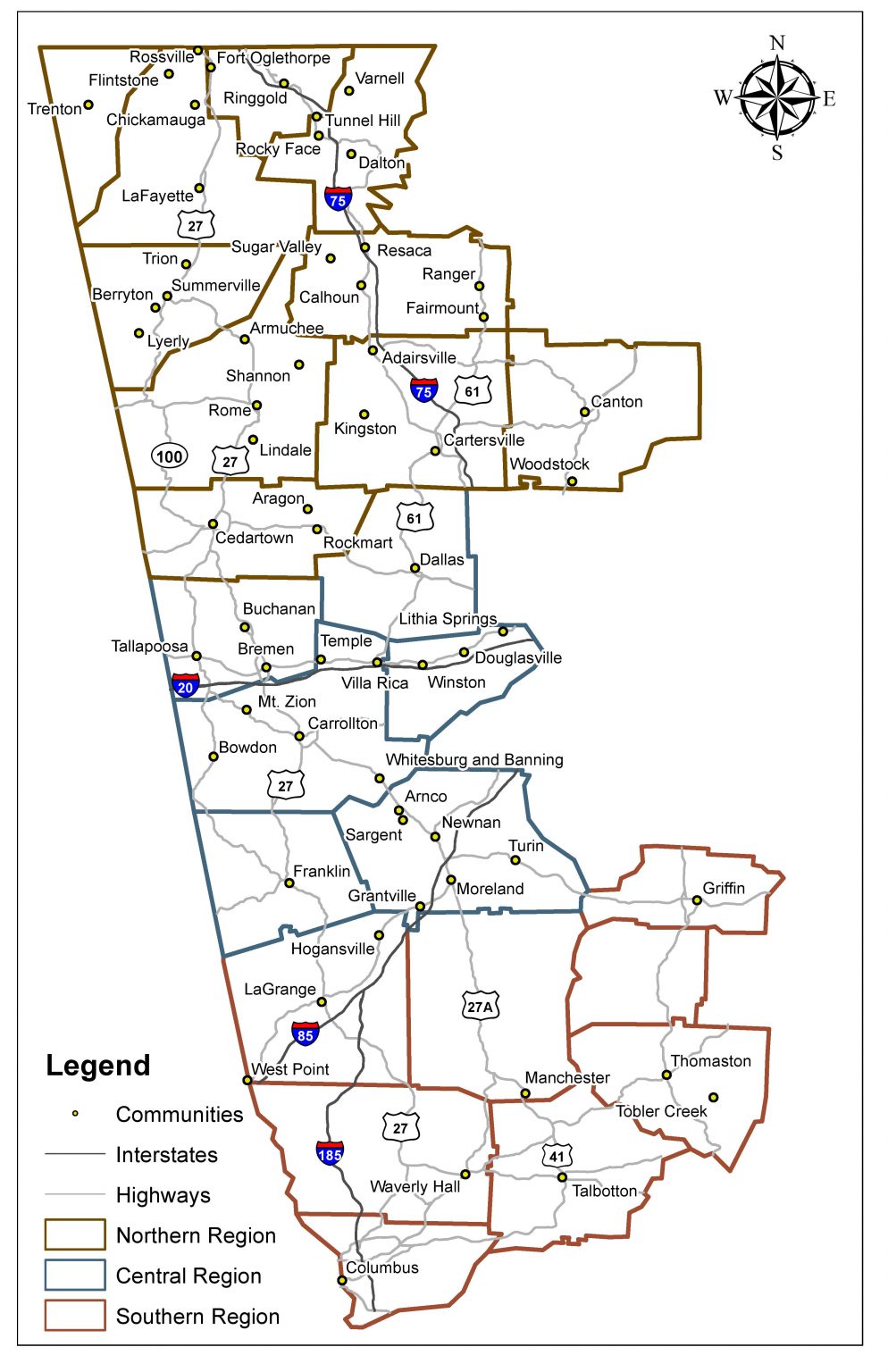

Back to Community List

Email the Trail at wgtht@westga.edu or visit our Contact Us page for more information.