This creek was home to several textile mills due to its intense waterpower.

Visit

Things to Do

- Flint River Canoeing, 4429 Woodland Road: Water travel and water power were crucial for operating most mills in this region. In Upson county, the best place to get started canoeing the Flint River is the Flint River Outdoor Center, which is located at 4429 Woodland Rd. The Outdoor Center offers equipment rental and shuttle service. Contact them by phone (706-647-2633) for information on weather, river conditions, and canoe rental. The river is mostly calm, and flows past beautiful bluffs, woods, and shoals. There are light to medium rapids scattered throughout the river, depending on the water level.

- Thomaston-Upson Archives, 301 South Center Street: The Archives are the official repository of the governmental and historical documents of Upson County. They also contain much of the Upson Historical Society’s collection along with documents and items donated by private individuals. Its library contains county and city census and court records, newspapers from 1833 to today, school records, and a large amount of genealogical books, records and manuscripts. The basement contains a meeting hall seating ninety people. The Archives are open weekdays.

Places to See

- While none of the factories mentioned still stand, the ruined foundations still exist. It should be noted that these are currently on private property and should not be explored without permission.

History

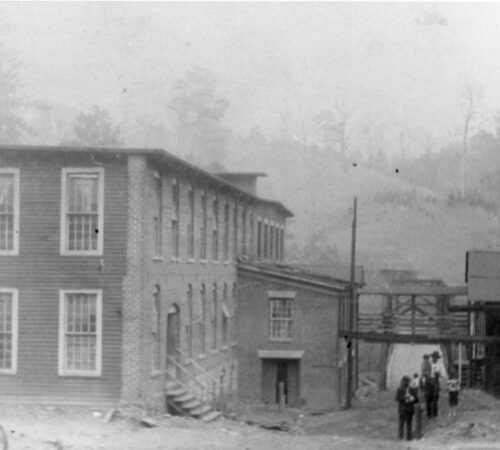

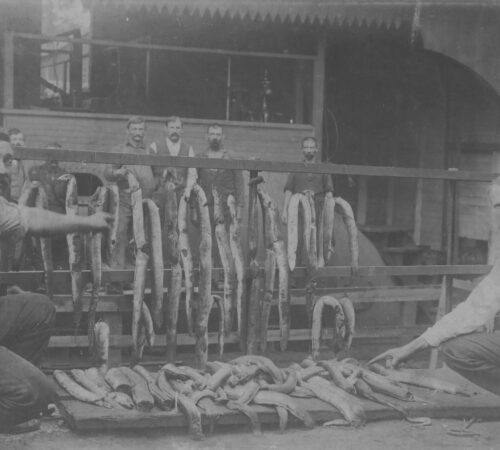

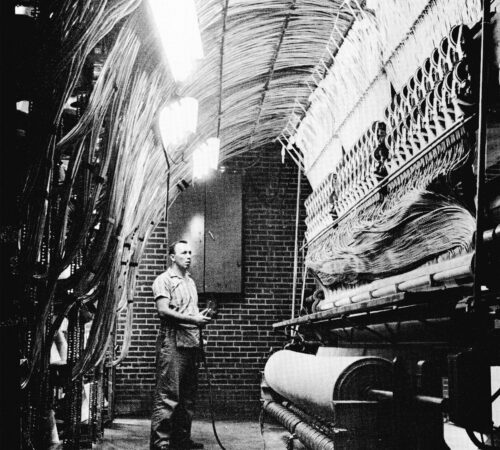

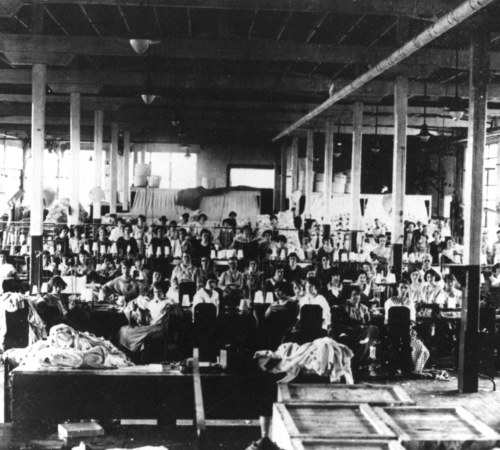

Courtesy of the Thomaston-Upson Archives

Upson County was among the first areas in Georgia to receive industrial development, largely owing to its position on the Fall line. The first part of Upson to be developed was Tobler Creek in the southeastern section of the county. Dwight Perry and William Waynman, New England textile men and brothers-in-law, spearheaded the investment group which founded Franklin Factory on Tobler Creek in 1833. Waynman was killed during the factory’s construction, but he was soon replaced by yet another brother-in-law, George P. Swift. The Franklin Factory was a decent sized operation; by 1849 it was able to boast a respectable 1,320 spindles and 16 carding machines.

In the same year as Franklin Factory was founded, Walker & Grant established Flint River Factory at the confluence of the Flint River and Tobler Creek. In 1849, the factory could list a respectable 1,560 spindles, 16 cards, and 26 looms as assets, while employing 50 people. The factory used around 700 lbs. of cotton per day.

Swift went on to found Waynmanville Factory just south of the Franklin Factory on Tobler Creek in 1841. By 1849, it featured a mill village and was equipped with 1,664 spindles and 26 looms which produced heavy osnaburgs. Between the Franklin and Waynmanville factories, 1,100 bales of cotton were used per year and 125 people were employed.

At the same time as Waynmanville was being built, Thomaston Manufacturing Company was opened on Potato Creek just north of the town. This operation was bolstered by the building of a railroad that linked Thomaston with Barnesville in 1856. From a logistical standpoint, this made Thomaston the more desirable location for mills when compared with its contemporaries that were located on Tobler Creek. Despite the disadvantage, the mills on Tobler Creek continued to prosper until 1865.

The Civil War wound up being a catastrophe for Upson County, as well as the other industrial areas in Mid-west Georgia. In the waning weeks of the war, Union cavalryman James Wilson led a raid which saw factories from West Point to Columbus burned to the ground. Upson County was no exception, all but one of the Upson mills were destroyed. Rogers Factory never reopened, while Franklin Factory escaped the cavalry only to burn down in 1870.

Courtesy of the Thomaston-Upson Archives

George Swift managed to use the destruction to his advantage. He reopened and expanded Waynmanville Factory and purchased the Flint River Factory, renaming the mill village Swifton. At the same time, he switched his focus to Columbus, where he led a group that established the Muscogee Manufacturing Company in the old Coweta Falls mill building. In the process, he founded a Columbus textile dynasty which would last for 100 years. However, this expansion did not mean that his Upson mills were neglected. In partnership with the local Respess family, Swift expanded the Flint River factory to 3,500 spindles in 1870 and 4,000 by 1881. Meanwhile at Waynmanville, Swift entered into a partnership with yet another Columbus textile man, Louis Hamberger. Together they formed Swift, Hamberger & Co. By 1888 they had expanded Waynmanville to 64 looms and 3,300 spindles powered by water.

Courtesy of the Thomaston-Upson Archives

However, in 1889, Swift’s business in Upson County was drawing to an end. The mill at Swifton burned, leaving Waynmanville as Upson’s last functioning textile mill. By 1895, two years before the end of his life, Swift was bought out of Waynmanville by Louis Hamberger. Hamberger continued to slightly expand Waynmanville until he sold it. The mill would continue operations with gradual expansions, which eventually reached 4,800 spindles, until 1909, when the owners elected to move operations to Forsyth in Monroe County. Textile operations in Southeastern Upson County died with Waynmanville, but their legacy was carried on by the Hightowers in Thomaston.

Charter Trail Members

Resources to Explore

Click on the following links to learn more about this region.

- Thomaston Community Page

- Digital Library of Georgia

- Georgia Archives Virtual Vault

- Georgia Historical Society

- Upson County, New Georgia Encyclopedia

Back to Community List

Email the Trail at wgtht@westga.edu or visit our Contact Us page for more information.