This community’s short-lived textile industry provided jobs for many of the county’s citizens.

Visit

Things to Do

- Buchanan-Haralson Public Library, 145 Van Wert Street: This library hosts a local history room and images that include the region’s textile history.

- Historic Haralson County Courthouse, 145 Van Wert Street: Located in downtown Buchanan and constructed in 1891, it is one of the oldest working courthouses in Georgia. It was placed on the National Register of Historic Places in 1974.

- Little Creek One Room Schoolhouse, 159 Van Wert Street: In existence since 1871, it is the last one-room schoolhouse left in Haralson County, and one of the few in the state. The building was operational until 1932.

Places to See

The following properties are not open to the public, but you can view them from the exterior to learn more about the buildings that supported the textile industry here.

- Cluett Building, 155 Van Wert Street: While this building houses a business that is not textile-related, the original textile building still stands.

History

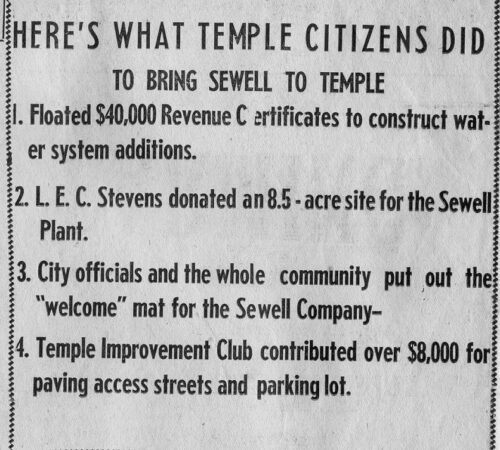

Founded as the county seat of Haralson County in 1856 and named in honor of President James Buchanan, the city of Buchanan’s textile heritage began with Cluett, Peabody, and Company. In 1947, Cluett, Peabody and Company opened a shirt manufacturing facility in Buchanan, producing Arrow Shirts. As part of the Southern division of Cluett, Peabody & Co. Inc., the finished goods produced at the Buchanan facility were shipped to the Atlanta plant. The Arrow plant employed many of the citizens of Buchanan and Haralson County until it closed in the early 1990s due to increased foreign competition.

In 1948, Cluett, Peabody and Company produced a documentary titled Enterprise to explain their journey of moving into Buchanan. This documentary explores the town’s building of a textile mill and their experience getting the producer of Arrow shirts to move in.

Charter Trail Members

- Buchanan-Haralson Public Library

- Greater Haralson Chamber of Commerce

- Greater Haralson Tourism

- Haralson County Historical Society

Resources to Explore

Click on the following links to learn more about this region.

- Facts for Kids

- Digital Library of Georgia

- Georgia Archives Virtual Vault

- Georgia Historical Society

- Haralson County, New Georgia Encyclopedia

Back to Community List

Email the Trail at wgtht@westga.edu or visit our Contact Us page for more information.